CNC F1 Model

CNC F1 Model

Our company was founded in 1990 manufacturing hydraulic transfer macnines.Our first ADVANCED model CNC was produced on 2001.at least lately n 2006,we started producing CNC F-1 MODEL transfer machine.Continued... Robotic Automation

Robotic Automation

We contunue to our cooperation with high precise Professional robot manufacturer Mitsubishi robotics.Continued...

Solution Partners

Robotic Loading Machines

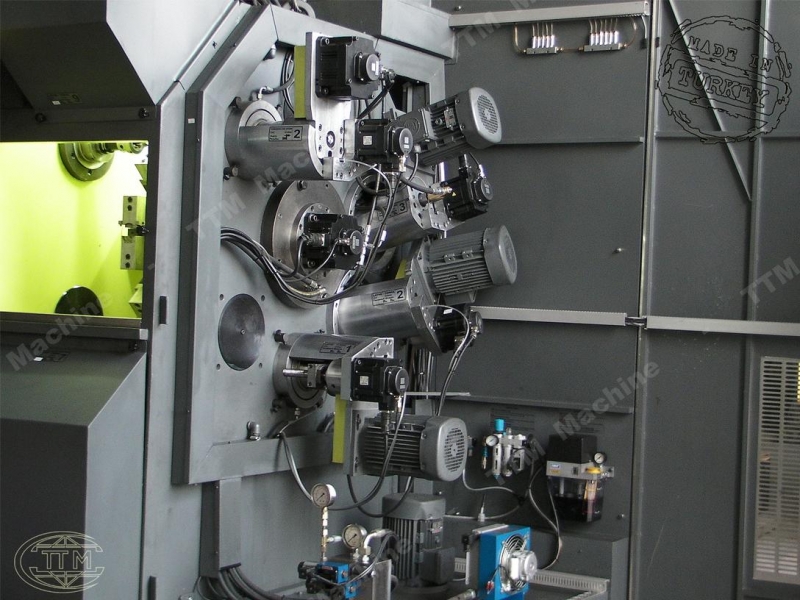

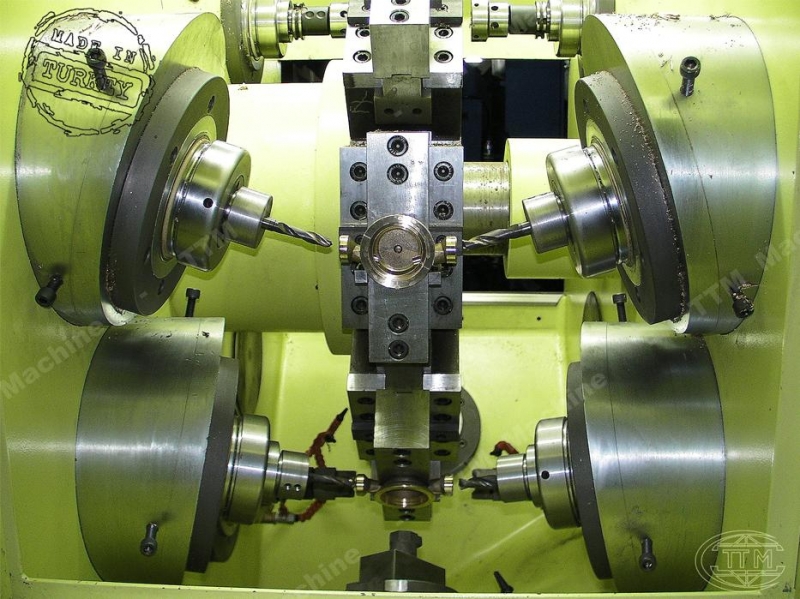

CNC-F1-Plus Model Transfer machine is coequal of, high performance, high flexibility and sensitive process in small tolerances. With fully manless robotic working property, we can optimize maximum productivity and minimum production cost so nowadays, at these competition conditions this choice becomes unpaired choice with no alternatives for industrialists. –F1- Plus Transfer is appointed servos with absolute encoders and it aims solving proplems effectively with its rigit working at high speed properties. With its that structure, CNC –F1- Plus Transfer which uses last technology equipments and processes, between other mass production methods the most developed and smooth solution.

Unit structure are driven with totally absolute servo motors, turret has High Speed Cylo technology and for manless working function FANUC 200IC/200IB model robotic loading properties coming into prominence. This model can be produced as with vertical or horizantal axis and 4 ,6 ,8 ,10 ,12 station.

Standed Out General Standard Properties :

· Servo Turret has High Speed Cyclo technology with 17 tone locking pressure. Servo turret can be with index or without index.

· Multi Turn Absolute Servo motor control, double guide, high accuracy, rigid unit structure.

· Manless loading with Fanuc 200iC / 200iB robot loading and FACTOR-H vibrobunker.

· Ultra compact technologic design which reserve electric, hydroulic and robot group at one body.

· Protections of work accident people prevention with beam barrier.

· Multi functionTTM Motion user software.

· User friendly easy usage programming pages interface or G-Kode programming language.

· High frequency, 32 bit, colorful, 15 inch big screen touch screen control panel.

· Over internet with Ethernet remote help and program version upgrade potential.

· Easy usage with detailed fault notice.

· BONFIGLIOLI Gearbox driven helical turnings conveyor, suitable to Steel and brass.

· Stainless Steel covered –F1- model exterior construction design.

· Full automatic VOGEL multi point oiling unit.(including all slides, threaded rods and guides).

Optional Properties:

· TEDİSA turret index gear with 360 gear fully grinded +0,002 mm repeating precision.

· 0,5 Sec/station and less velocity with ultra High Speed turret turning.

· With primary tension NSK unit drive threaded rod with +0,005mm precision.

· From inside of tool liquid injection and cooling system from spindle up to 20 bar.

· 19 Inch big touch screen control panel.

· Information messages and control options over GSM network.

Automatic Robotic Loading:

· FANUC 200IC / 200IB 6 axis robot.

· R30iA Mate Robot controller.

· +0,02mm Position precision.

· 704 mm Arm length.

· Maximum 5 kg piece holding. (Inclusive Grippers).

· Single or couple Gripper usage.

· Factor-H Vibrobuncer.

· *Piece recognation system with camera control.

Construction :

· Made from 40, 50,60 mm St 37 Platina rigit weld construction.

· Average total weight is 4000 – 12000 kg (it can change proportional to station and unit number).

· Stainless Steel covered –F1- model exterior construction design.

· Acrylic paint which is durable external forces.

Turret :

· GGG 60 Sphero single or couple Groove.

· 17 Tone locking pressure.

· 4,5,6,8,10 and 12 Station model option.

· With index or without index servo turret which has High Speed Cyclo technology.

· At high resolution Multi Turn Absolute Servo turning.

· With half station stopping, easy tool changing.

· %100 TTM production except index geared and CYCLO turning.

· *0,5 Sec/station or less velocity with Ultra High Speed turret turning.

· *TEDİSA turret index gear with 360 gear fully grinded +0,002 mm repeating precision.

Chucks :

· 100 ,125 ,300 Three type chuck size.

· Hydraulic driven.

· Regulatable tong pressure (at 100 max 800 kg/ at 125 max 3000 kg / at 300 max 6500 kg).

· With oiling lubricator from one point.

· 100% TTM manufacture.

· *Tong with core which provide couple piece holding.

Hydraulic System :

· Vickers / Parker / Rexroth hydraulic pomp.

· 35 – 60 Bar working pressure.

· Vickers / Parker / Rexroth NG-6, 24 Volt on off control valves.

· Chuck pressure control valve.

· Main system and chuck pressure indicators.

· Hydraulic hose with fully press recor with 150 bar endurance.

· Totally coupled and assembly by TTM.

· *EMMEGİ / HYDAC hydraulic oil cooling.

· *1 - 4 Lt hydraulic battery.

Electrical System:

· 380-400 Volt main electric feeding.

· Moeller ve Omron Şalt switchgear components.

· Electrical cabinet with filtered ventilation.

· Reverse phase protection relay.

· Group 2 relay of prohibit working accident.

· Illumination of machining centers and panel.

· Front, back neon warning and information light group.

· Totally assembly by TTM.

· *Closed loop board cooling with air-condition.

Servo Motor Group :

· MITSUBISHI 1, 1,5, 2, 3, 4 Kw Servo motors.

· Multi Turn Absolute 262.000 x 4 pulse encoder group.

· High technology Mitsubishi MR-J3 Series driver group with optical communication.

· *SIEMENS Servo motors and control unit.

AC Motor Group :

· WATT 1,5 / 2,2 / 3 / 4 / 5,5 / 7,5 Kw 1500 / 3000 rpm asynchronous motors.

· HERTZ 12000 / 18000 High rotation motors.

· *Rotation control with invertor.

· *Siemens asynchronous motors.

Controller Group :

· MITSUBISHI Q Series Motion control.

· Multi function TTM Motion user software which has high flexibility.

· User friendly easy usage programming pages interface or G-Kode programming language.

· High frequency, 32 bit, colorful, 15 inch big screen touch screen control panel.

· Automatic servicing warning.

· Multi function fault notice.

· I/O Diagnostics.

· Over internet with Ethernet remote help and program version upgrade potential.

· With detailed fault warning easy usage and remote fault determination support (with Ethernet over internet).

· User friendly with easy usage and patent, 100% TTM design.

· *19 Inch big touch screen control panel.

· *İnformation messages and control options over GSM network.

· *SIEMENS control group. (It can use with only SIEMENS Servo motors).

Turning Conveyor and Other Properties :

· BONFIGLIOLI Gearbox driven helical turnings conveyor, suitable to Steel and brass.

· Fully automatic VOGEL multi point greasing unit. (Including all slides, threaded rod and bearing).

· Ultra compact technologic design which reserve electric, hydroulic and robot group at one body.

· More economic in virtue of high technology smart motors and drivers.

· Very fast and sensitive different part changing conformation in virtue of fully servo drive without mechanical calibration.

· User friendly as children can use with TTM Motion software’s simple interfaces.

General Unit Properties:

· Rigid unit structure, Multi Turn Absolute Servo control, double guides high precision.

· Positioning with NSK or equivalent threaded rod.

· High precision Second guiding with low space and no space NSK linear slide.

· Aluminum, zamak, brass, bronze, Steel, gray cast iron , nodular cast iron, forged Steel etc. machining capacity.

· Totally patented, coupled and assembly by TTM.

· *With DAUBLIN giving high pressure (max 20 bar) water inside tool from inside spindle.

· *Tool abrasion detector and warning system.

- Mechanical Hardware

TTM moves with maximum care about both machining methods and right, qualified raw material purchasing. All of the mechanical equipments which produced within TTM, materials are selected as Steel and also starting with certificated products to over machinedContinued... - Imported Mechanics

TTM presents that, at auxiliary ready components of produced sensitive machining product groups, space less, and zero backlash equipments are selected so flawless, sensitive and long lived products are used.At spindle ball bearing groups of units, Japanese NSKContinued... - Electrical Hardware

We adopted as a principle that, we use qualified and long lived equipments at all machines which we have produced. Our basic consumption products are at switchgear components German MOLLER, at energizer signal transmission safeties Japanese OMRON Continued... - Machine Control

TTM has partners as Japanese MITSUBISHI and Austrian KEBA for machines’ controller group. As all the users know that, operator and controller software has effect directly to machine performance, capacity and usability.Although a machine is designed ideally,Continued...